PRODUCT CENTER

VF Leafy Vegetable Cutter

Equipped with an advanced dual inverter control system, this machine delivers independent regulation of conveyor belt feeding speed and blade rotation speed. This allows for real-time, precise adjustment of cutting sizes that perfectly match your specific production requirements.

Product Details

▶ Introduction to VF Leafy Vegetable Cutter

MK-200 Single-Head Vegetable Cutting Machine is engineered for professional kitchens and food processing operations that demand exceptional cutting precision and hygiene. Its innovative removable conveyor belt design allows for quick disassembly and effortless cleaning, ensuring compliance with strict food safety standards.

Featuring an advanced dual-frequency conversion system, this cutter provides independent control over both belt feed speed and blade rotation. This enables real-time, precise adjustment of cutting dimensions—producing consistent slices, sections, or strips to meet your exact specifications.

Constructed entirely from hygienic SUS304 stainless steel, the machine offers durability, corrosion resistance, and a clean, professional appearance. An integrated safety micro-switch on the discharge door immediately halts operation when accessed, prioritizing user protection.

Ideal for processing leafy greens, cucumber sticks, zucchini, carrot strips, and similar vegetables, the MK-200 Single-Head Vegetable Cutting Machine efficiently delivers uniform slices, segments, or adjustable-length strips—making it a versatile and reliable solution for high-volume, high-standard food preparation.

▶ Parameter

▶ The Advantages of VF Leafy Vegetable Cutter

✔ Enhanced Durability & Hygienic Construction

All machine frames are constructed with high-grade stainless steel, featuring a premium brushed finish. This ensures superior resistance to corrosion, wear, and frequent washdowns, providing long-term reliability in demanding food-processing environments.

✔ Intuitive Touchscreen Control

Operation is simplified through a responsive touchscreen interface. The user-friendly panel allows for easy programming and real-time adjustments, reducing training time and minimizing operational errors for enhanced productivity.

✔ Quick-Release Conveyor Belt System

The conveyor belt is equipped with a quick-release mechanism, enabling rapid removal without tools. This design facilitates effortless cleaning, sanitation, and replacement, supporting strict hygiene protocols and reducing downtime between batches.

✔ Fully Adjustable Processing Speeds

Both the conveyor belt speed and cutting blade speed can be independently adjusted. This dual-control capability offers exceptional flexibility to handle a wide variety of vegetables and achieve precise cut sizes—from delicate slices to uniform strips.

✔ Stable Material Handling for Precision Cutting

An integrated material pressing mechanism securely holds vegetables in place during conveyance. This prevents slippage and misalignment, ensuring every cut is consistent and accurate for higher-quality end products.

✔ Complete Waterproof Design for Easy Cleaning

The entire unit is designed with full waterproof protection, allowing for thorough and worry-free washing. This feature promotes optimal hygiene, meets food safety standards, and simplifies daily maintenance routines.

Equipment Details Display

Control panel can realize variable frequency speed regulation,cutting mode selection and real-time feedback of equipment operating status,and is the core component for controlling the precise operation of the variable frequency vegetable cutter.

Control panel can realize variable frequency speed regulation,cutting mode selection and real-time feedback of equipment operating status,and is the core component for controlling the precise operation of the variable frequency vegetable cutter. Conveyor belt can uniformly and continuously transport the ingredients to be cut to the cutting area, cooperate with the cutting blades to complete standardized cutting, and conveyor belts also have anti-slip and easy-to-clean properties to meet the usage requirements of the kitchen.

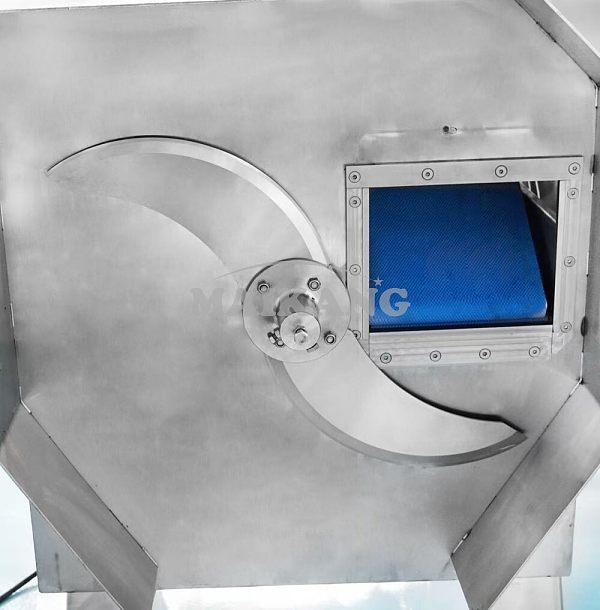

Conveyor belt can uniformly and continuously transport the ingredients to be cut to the cutting area, cooperate with the cutting blades to complete standardized cutting, and conveyor belts also have anti-slip and easy-to-clean properties to meet the usage requirements of the kitchen. A special vegetable cutting knife adapted to variable frequency drive systems with intelligently adjustable rotational speed. It can flexibly adjust the cutting speed according to ingredient types/cutting requirements, boasts both durability and cutting precision, and is suitable for diverse vegetable cutting scenarios.

A special vegetable cutting knife adapted to variable frequency drive systems with intelligently adjustable rotational speed. It can flexibly adjust the cutting speed according to ingredient types/cutting requirements, boasts both durability and cutting precision, and is suitable for diverse vegetable cutting scenarios.

Product Video

Company Strength

MAIKANG is a trusted manufacturer and provider of food machinery solutions, dedicated to the mission of "delivering customized and integrated equipment to enhance food production efficiency and value." Partnering with our clients, we tackle industry challenges and unlock new opportunities, achieving sustainable growth and creating lasting value.

MAIKANG is established in 2014 and located in Zhucheng city, Shandong province of China. It specializes in supplying reliable automated food processing equipment, including fruit and vegetable cleaning and juicing lines, industrial washing machines, pasteurization and cooling lines, blanching and cooling lines, cooking machines, and more. We provide competitive food processing solutions to clients both domestically and internationally, earning widespread praise for its dependable products and dedicated service.

Online Consultation

Products Recommended