Processing Lines for Salads and Leafy Greens

Maikang's processing lines for salads and leafy greens are engineered to meet the highest quality standards, delivering thoroughly cleaned, ready-to-eat vegetables. The integrated system features high-efficiency equipment for cutting, washing, drying, sorting, and packaging a wide variety of leafy produce—from lettuce and cabbages to spinach, parsley, celery, and beyond.

Designed for flexibility, each production line can be configured to match your target output, with capacities ranging from 500 kg to over 1500 kg per hour. The modular design allows you to begin at a scale that suits your needs and expand seamlessly as your business grows.

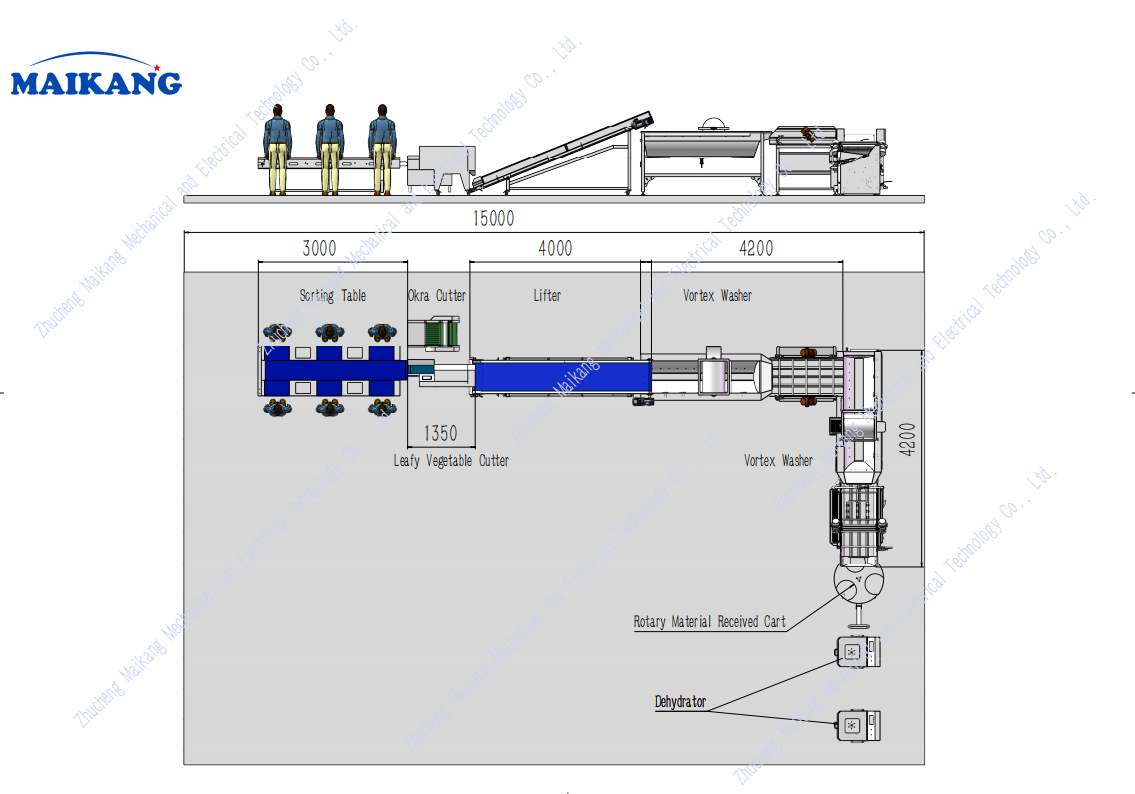

Our salad processing equipment is designed to extend the shelf life of your products and keep them fresh longer. For leafy vegetables with high levels of soil and microorganisms, a multi-stage washing system is recommended to ensure thorough cleaning. To achieve complete sterilization, we employ a two-stage washing process: first sanitizing the produce, then rinsing it with clean water. An optional chiller can be added to enable cold-water washing. Since salads and leafy greens are ready-to-eat, dual-stage washing provides essential extra assurance—typically involving a primary vortex washer followed by a secondary vortex washer. You can refer to the diagram below for a clearer understanding of how it works.

This line includes:

✓ 1.Sorting Table

✓ 2.Leafy Vegetable Cutter

✓ 3.Lifter

✓ 4.Primary Vortex Washer

✓ 5.Secondary Vortex Washer

✓ 6.Rotary Materials Received Cart

✓ 7.Centrifugal Dehydrator

Gallery

1. Sorting Table

Positioned at the cutting machine entrance, the sorting table allows workers to de-core, de-stem, and pre-cut leafy vegetables on dedicated cutting boards, with waste funnels for disposal. Processed vegetables are then fed directly into the cutter. The station can be configured with 2, 4, or 6 work positions.

2. Leafy Vegetable Cutter

Our vegetable cutting machine features an innovative detachable conveyor belt for quick disassembly and easy cleaning, ensuring full compliance with strict food safety standards. It is equipped with an advanced dual inverter control system, allowing independent adjustment of both conveyor feed speed and blade rotation speed, with a cutting size adjustable from 1 to 40mm.

3. Lifter

Cut vegetables are elevated and fed into the primary vortex washing machine.

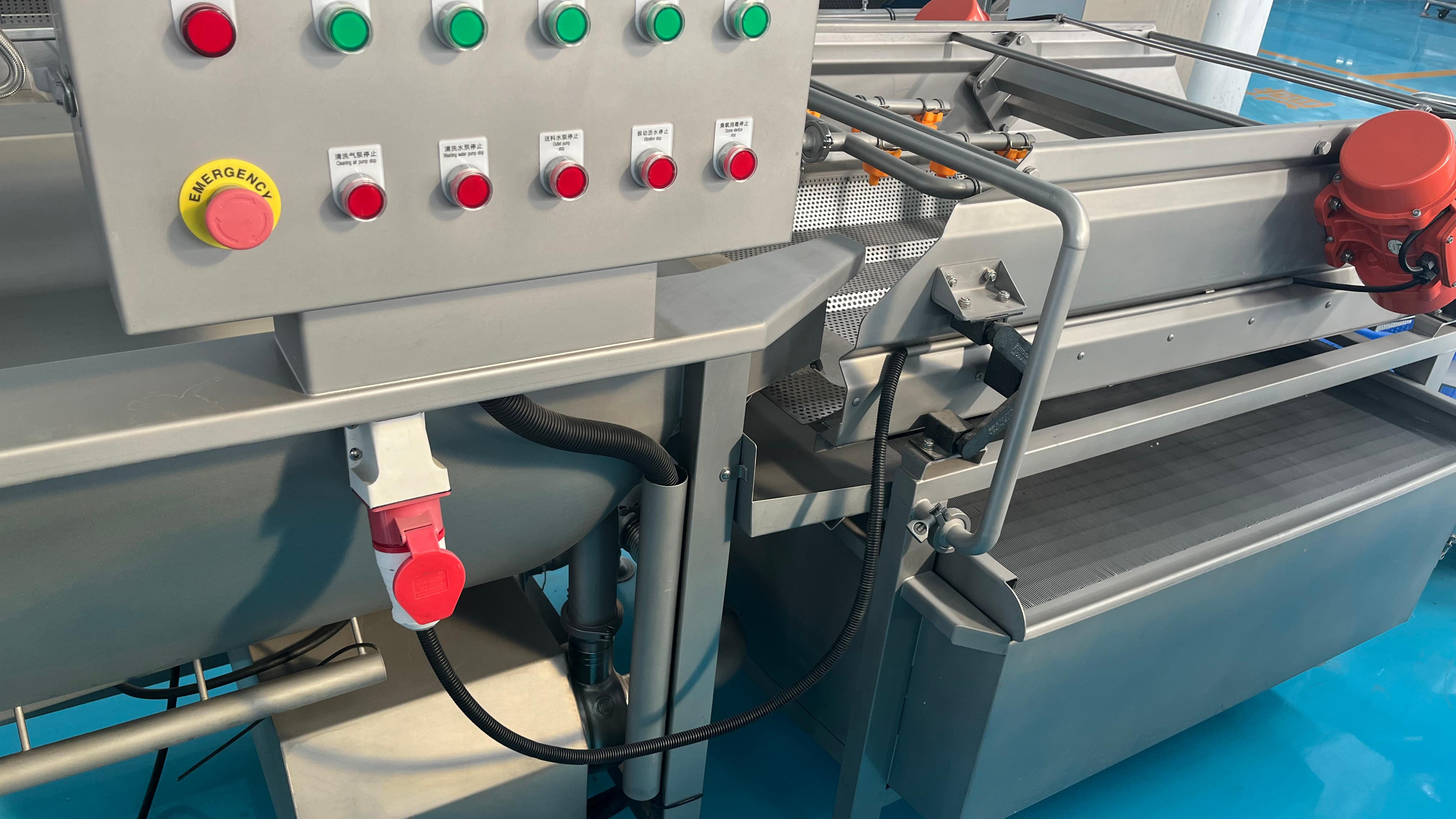

4. Primary Vortex Washer

This machine gently cleans the cut or whole leafy greens using the vortex and bubbles it generates, ensuring no damage occurs. It creates a vortex with purified water, immersing the materials in the swirling flow for thorough cleaning. Inside the tank, materials spiral along with the water. Small leaves and insects, foams can be filtered out and sanitizing agents and detergents can be added to the water solution if necessary. Once cleaned, they are carried forward by water flow to a vibrating conveyor, which then discharges them from the machine.

5. Secondary Vortex Washer

The secondary vortex washer then acts as a critical assurance and refinement stage. It further reduces microbial load, eliminates any potential residual cleaning agents from the first stage, and provides a final rinse in clean, sanitized water. This dual-stage approach significantly mitigates cross-contamination risks and is a recognized good practice for ensuring pathogen reduction. Ultimately, it delivers an extra layer of protection, ensuring the final product complies with stringent international food safety and hygiene regulations, such as HACCP standard.

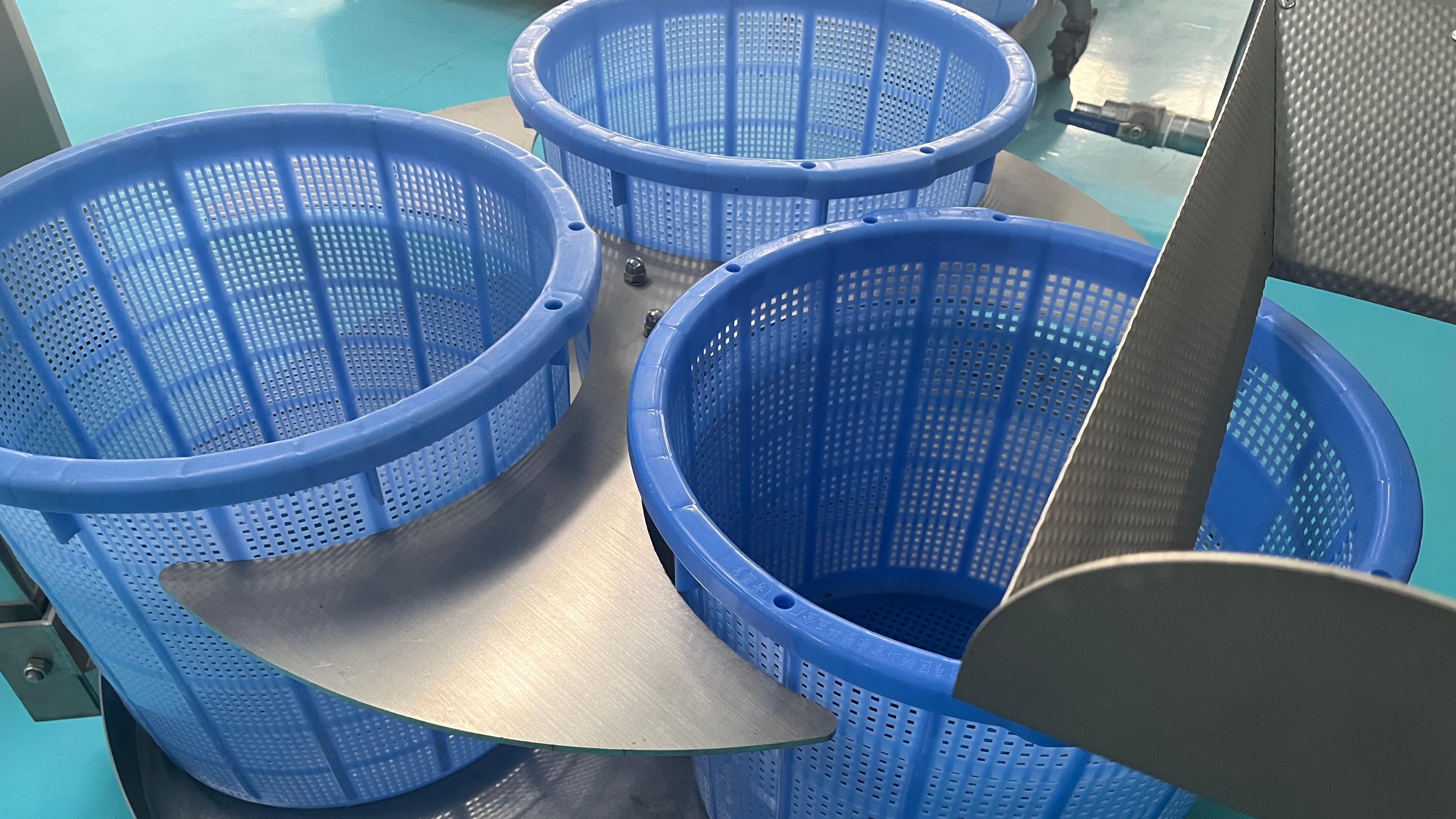

6. Rotary Materials Received Cart

Customized to client specifications, our rotating receiving carts come in manual way and fully automatic models, each integrated with plastic crates for efficient collection and handling. It is installed after the washing machine to collect the washed leafy vegetables.

7. Centrifugal Dehydrator

The centrifugal dehydrator provides efficient drying for fresh-cut and leafy vegetables. After washing, produce is loaded into the basket, where high-speed rotation removes excess water and surface moisture. Rotation speed and cycle time are fully adjustable, allowing gentle yet effective drying tailored to each product type—preventing damage from over-spinning.

Online Consultation